Through Hole Assembly Operator

In the realm of electronics manufacturing, the intricate process of assembling circuit boards demands precision, expertise, and attention to detail. Among the crucial roles within this process is that of the Through-Hole Assembly Operator. These skilled professionals play a pivotal role in ensuring the integrity and functionality of electronic devices. In this article, we delve into the responsibilities, skills, and significance of Through-Hole Assembly Operators in today’s technology-driven world.

Introduction to Through-Hole Assembly:

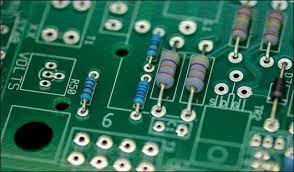

Through-hole assembly is a method used in electronic circuit board assembly where components are inserted into holes drilled through the board and then soldered in place. This method contrasts with surface-mount technology (SMT), where components are mounted directly onto the surface of the printed circuit board (PCB). Through-hole assembly was traditionally the dominant method of assembling circuit boards before the rise of SMT, and it is still widely used today, especially for components that require higher mechanical strength or higher power handling capabilities.

Role of Through-Hole Assembly Operator:

Through-Hole Assembly Operators are responsible for carrying out the assembly process with meticulous attention to detail. Their primary duties include:

- Component Insertion: Through-Hole Assembly Operators meticulously insert electronic components such as resistors, capacitors, diodes, and integrated circuits into the pre-drilled holes on the PCB according to the specifications provided in the assembly instructions.

- Soldering: Once the components are inserted, Through-Hole Assembly Operators solder them onto the PCB to ensure electrical connectivity and mechanical stability. This process requires precision and skill to avoid solder bridges or insufficient solder joints that could compromise the functionality of the circuit.

- Quality Control: Through-Hole Assembly Operators are responsible for inspecting their work at each stage of the assembly process to ensure that components are correctly placed, soldered, and aligned. They must also identify and rectify any defects or discrepancies to maintain the quality standards of the finished product.

- Equipment Maintenance: Through-Hole Assembly Operators are often tasked with maintaining and calibrating the assembly equipment, such as soldering irons, solder pots, and inspection tools, to ensure optimal performance and accuracy.

- Adherence to Safety Protocols: Working with electronic components and soldering equipment requires adherence to strict safety protocols to prevent injuries and accidents. Through-Hole Assembly Operators must be knowledgeable about safety procedures and regulations governing their work environment.

Skills and Qualifications:

To excel as a Through-Hole Assembly Operator, individuals must possess a unique blend of technical skills, attention to detail, and manual dexterity. Some essential skills and qualifications include:

- Technical Aptitude: Through-Hole Assembly Operators should have a strong understanding of electronic components, circuitry, and soldering techniques. They must be able to interpret assembly instructions, schematics, and technical drawings accurately.

- Manual Dexterity: The ability to work with small components and delicate circuit boards requires excellent hand-eye coordination and manual dexterity. Through-Hole Assembly Operators must be capable of handling tools and components with precision and care.

- Attention to Detail: A keen eye for detail is essential to ensure that components are correctly placed, aligned, and soldered according to specifications. Even minor errors or defects can impact the functionality and reliability of the finished product.

- Problem-Solving Skills: Through-Hole Assembly Operators should be adept at troubleshooting and problem-solving to identify and resolve issues that may arise during the assembly process. This may involve diagnosing soldering defects, component misalignment, or equipment malfunctions.

- Teamwork and Communication: Collaboration with other team members, such as engineers, quality inspectors, and supervisors, is often necessary in the assembly process. Through-Hole Assembly Operators should possess strong communication skills and the ability to work effectively as part of a team.

Significance of Through-Hole Assembly Operators:

Through-Hole Assembly Operators play a crucial role in the manufacturing of electronic devices across various industries, including telecommunications, automotive, aerospace, and consumer electronics. Their expertise ensures the reliability, functionality, and quality of electronic products that are integral to modern life.

Despite the growing popularity of surface-mount technology, through-hole assembly remains a preferred method for certain applications due to its advantages in terms of mechanical strength, thermal dissipation, and ease of repair and rework. Through-Hole Assembly Operators uphold the standards of quality and craftsmanship that are essential for producing high-performance electronic devices.

Moreover, as technology continues to advance and new innovations emerge, the demand for skilled Through-Hole Assembly Operators remains steady. Their contributions to the manufacturing process are invaluable in driving technological progress and innovation in the electronics industry.

Conclusion:

Through-Hole Assembly Operators are the unsung heroes behind the scenes of electronic manufacturing, ensuring that the intricate components of circuit boards come together seamlessly to create functional and reliable devices. Their expertise, attention to detail, and commitment to quality are essential for maintaining the integrity and performance of electronic products in today’s technology-driven world. As technology continues to evolve, the role of Through-Hole Assembly Operators remains indispensable in shaping the future of electronics manufacturing.