Pick And Place Assembly Operator

In the realm of manufacturing, efficiency and precision are paramount. Whether it’s in electronics, automotive, pharmaceuticals, or any other industry, the process of assembling intricate components demands a delicate balance of human skill and technological prowess. At the heart of this process lies the Pick and Place Assembly Operator, a vital role that bridges the gap between manual dexterity and automated machinery.

Understanding Pick and Place Assembly

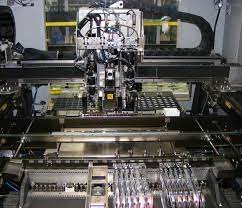

The Pick and Place Assembly process involves the automated placement of components onto a substrate or printed circuit board (PCB). This process is ubiquitous in industries where precise positioning of small parts is required, such as electronics manufacturing, semiconductor fabrication, and packaging.

Pick and Place machines, also known as placement systems or chip shooters, are automated equipment designed to swiftly and accurately pick up components from a supply source and place them onto the designated areas of a substrate. These components can range from tiny surface mount devices (SMDs) to larger parts depending on the application.

The Role of Pick and Place Assembly Operators

While Pick and Place machines handle the bulk of the assembly work, the human touch is indispensable, especially in ensuring the smooth operation of the assembly line and maintaining the quality standards of the final product. Pick and Place Assembly Operators play a pivotal role in this regard, serving as the linchpin between technology and craftsmanship.

Responsibilities of Pick and Place Assembly Operators:

- Machine Setup and Calibration: Before the assembly process begins, operators are responsible for setting up the Pick and Place machines according to the specific requirements of the job. This involves loading component reels, adjusting machine settings, and calibrating the equipment to ensure precise placement.

- Quality Control: Throughout the assembly process, operators must continuously monitor the quality of the assembled components. They inspect for defects, misalignments, or any other anomalies that could affect the functionality of the final product. Attention to detail is crucial in maintaining high-quality standards.

- Troubleshooting: Inevitably, issues may arise during assembly, such as machine malfunctions, component shortages, or programming errors. Pick and Place Assembly Operators are tasked with troubleshooting these problems quickly and efficiently to minimize downtime and prevent production delays.

- Material Handling: Apart from operating the Pick and Place machines, operators are often responsible for managing component inventory, replenishing supplies, and ensuring that the production line runs smoothly without interruptions due to material shortages.

- Adherence to Safety Protocols: Working in a manufacturing environment poses various hazards, from moving machinery to hazardous materials. Pick and Place Assembly Operators must strictly adhere to safety protocols to prevent accidents and maintain a safe working environment for themselves and their colleagues.

Skills Required for Pick and Place Assembly Operators:

- Technical Aptitude: Operators must have a good understanding of the assembly process, machine operation, and the components being used.

- Manual Dexterity: Precise hand-eye coordination is essential for tasks such as loading components onto feeders and inspecting assembled boards for defects.

- Problem-Solving Skills: The ability to troubleshoot issues and find solutions quickly is crucial for minimizing downtime and maximizing productivity.

- Attention to Detail: Even the smallest deviation from specifications can affect the functionality of the final product, making attention to detail a critical skill for Pick and Place Assembly Operators.

- Teamwork: Collaboration with colleagues across various departments is often required to ensure the smooth flow of production and address any challenges that may arise.

The Future of Pick and Place Assembly

As technology continues to advance, the role of Pick and Place Assembly Operators may evolve alongside it. Automation and robotics are becoming increasingly prevalent in manufacturing, leading to more sophisticated and efficient assembly processes. However, while machines can perform repetitive tasks with speed and accuracy, the human element remains essential for tasks that require creativity, adaptability, and critical thinking.

Furthermore, with the rise of Industry 4.0 and the Internet of Things (IoT), Pick and Place Assembly Operators may find themselves working alongside smart machines equipped with sensors and artificial intelligence capabilities. This integration of human expertise with cutting-edge technology has the potential to further enhance productivity, quality, and efficiency in manufacturing operations.

In conclusion, Pick and Place Assembly Operators play a vital role in modern manufacturing, combining technical expertise with manual dexterity to ensure the seamless operation of assembly lines and the production of high-quality products. As technology continues to advance, the role of these operators may evolve, but their importance in bridging the gap between human skill and automated machinery will remain indispensable.