Introduction: In the world of engineering and machinery, hydraulic and pneumatic systems play crucial roles in powering various operations. These systems utilize fluid power to transmit force, making them essential in industries ranging from manufacturing to aerospace. Understanding the mechanics behind hydraulic and pneumatic systems is key to appreciating their widespread applications and efficiency.

Hydraulic Systems: Hydraulic systems operate by utilizing pressurized fluids, typically oil, to generate mechanical power. They consist of several key components:

- Hydraulic Fluid: The fluid used in hydraulic systems must have specific properties, such as being non-compressible and resistant to temperature changes. Common fluids include mineral oil-based hydraulic fluids or synthetic fluids.

- Hydraulic Pump: The pump is responsible for generating the fluid flow within the system. It converts mechanical energy into hydraulic energy by pressurizing the fluid.

- Hydraulic Cylinder: Cylinders are used to convert hydraulic energy into linear mechanical force. They consist of a piston, rod, and cylinder barrel. When fluid pressure is applied, it acts on the piston, creating movement.

- Control Valves: Valves control the flow and direction of hydraulic fluid within the system. They regulate pressure, flow rate, and direction to manage the movement of actuators.

- Hydraulic Actuators: Actuators are devices that convert hydraulic energy into mechanical motion. They include hydraulic cylinders and hydraulic motors, which are used for linear and rotary motion, respectively.

Applications of Hydraulic Systems: Hydraulic systems find applications in various industries due to their high power density, precise control, and ability to handle heavy loads. Some common applications include:

- Construction Equipment: Hydraulic systems power heavy machinery such as excavators, bulldozers, and cranes, providing the force needed for digging, lifting, and moving materials.

- Aerospace: Hydraulic systems are used in aircraft for functions such as landing gear operation, flight control surfaces, and braking systems.

- Automotive: Hydraulic systems are found in vehicles for applications like power steering, braking systems, and automatic transmissions.

- Manufacturing: Hydraulic presses are used in manufacturing processes for forming, stamping, and forging operations due to their high force capabilities and precise control.

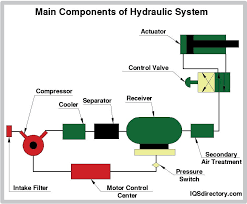

Pneumatic Systems: Pneumatic systems operate similarly to hydraulic systems but use compressed air instead of fluid to transmit power. They consist of similar components:

- Compressor: The compressor is used to compress atmospheric air, increasing its pressure and reducing its volume. This compressed air is then stored in a receiver tank for use in the system.

- Pneumatic Actuators: Actuators in pneumatic systems include cylinders and motors that convert compressed air energy into mechanical motion. Pneumatic cylinders operate by using the compressed air to move a piston, generating linear motion.

- Control Valves: Control valves regulate the flow of compressed air within the system, controlling the direction, speed, and force of pneumatic actuators.

- Air Preparation Unit: This unit includes components such as filters, regulators, and lubricators to ensure the quality of compressed air and protect the system components.

Applications of Pneumatic Systems: Pneumatic systems are widely used in industries where clean, dry air is readily available and where precise control and moderate force are required. Some common applications include:

- Manufacturing: Pneumatic systems are used in assembly lines for tasks such as material handling, pick-and-place operations, and automated packaging.

- Robotics: Pneumatic actuators are used in robotic systems for tasks that require fast and precise motion, such as gripping, lifting, and moving objects.

- HVAC Systems: Pneumatic controls are used in heating, ventilation, and air conditioning systems for functions such as damper control, valve actuation, and pressure regulation.

- Medical Equipment: Pneumatic systems are used in medical devices such as ventilators, dental drills, and surgical instruments due to their clean operation and precise control.

Comparison Between Hydraulic and Pneumatic Systems: Both hydraulic and pneumatic systems offer advantages and disadvantages depending on the specific application:

- Power Density: Hydraulic systems typically offer higher power density, making them suitable for heavy-duty applications that require high force output.

- Control and Precision: Hydraulic systems provide more precise control over force and speed, making them suitable for applications where accuracy is critical.

- Cleanliness: Pneumatic systems are generally cleaner than hydraulic systems since they use air instead of oil, making them preferred in environments where cleanliness is essential, such as food processing or medical applications.

- Maintenance: Pneumatic systems often require less maintenance than hydraulic systems since they have fewer components and do not rely on hydraulic fluid, which can degrade over time.

Conclusion: Hydraulic and pneumatic systems are integral parts of modern machinery and equipment, providing efficient and reliable power transmission for a wide range of applications. Understanding the mechanics of these systems allows engineers to design and optimize solutions tailored to specific needs, ensuring optimal performance and productivity in various industries. Whether it’s lifting heavy loads in construction or providing precise control in manufacturing, hydraulic and pneumatic systems continue to drive innovation and progress across different sectors.