Wafer Test and Sort Engineer

In the intricate world of semiconductor manufacturing, where minuscule components hold the key to technological advancement, every step of the process plays a pivotal role. Among the array of professionals contributing to this industry, Wafer Test and Sort Engineers stand out as crucial figures ensuring the functionality and reliability of semiconductor devices. In this article, we delve into the realm of Wafer Test and Sort Engineering, exploring their responsibilities, expertise, and significance in the semiconductor ecosystem.

Understanding the Basics

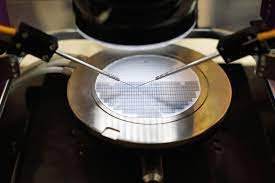

Before diving into the specifics of Wafer Test and Sort Engineering, it’s essential to comprehend the foundational concepts of semiconductor manufacturing. At the heart of this industry lies the fabrication of semiconductor devices, commonly referred to as integrated circuits (ICs) or chips. These chips are built on silicon wafers through a series of intricate processes involving deposition, lithography, etching, and doping.

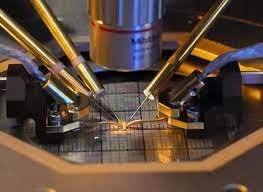

Once these processes are completed, the wafers undergo testing to ensure the integrity and functionality of the fabricated chips. This is where Wafer Test and Sort Engineers come into play.

The Role of a Wafer Test and Sort Engineer

Wafer Test and Sort Engineers are responsible for developing and implementing strategies to test semiconductor wafers comprehensively. Their primary objective is to identify defects, ensure the quality of manufactured chips, and sort them based on performance parameters. Let’s explore the key responsibilities of these engineers:

- Test Program Development: Wafer Test and Sort Engineers design and develop test programs tailored to the specific requirements of semiconductor devices. These programs include a series of electrical tests aimed at verifying functionality, performance, and reliability.

- Test Equipment Management: They oversee the operation and maintenance of test equipment, ensuring optimal performance and accuracy. This involves calibrating equipment, troubleshooting issues, and implementing upgrades to meet evolving testing needs.

- Data Analysis and Interpretation: Wafer Test and Sort Engineers analyze test data to identify patterns, trends, and anomalies. They interpret this data to assess the quality of fabricated chips and determine the root causes of any defects encountered during testing.

- Defect Diagnosis and Resolution: When defects are detected, Wafer Test and Sort Engineers work diligently to diagnose the underlying causes. They collaborate with process engineers and other stakeholders to implement corrective measures and optimize manufacturing processes to minimize future defects.

- Sort and Classification: Based on test results, Wafer Test and Sort Engineers classify semiconductor chips into different categories, such as good dies, marginal dies, and defective dies. This sorting process is crucial for ensuring that only high-quality chips are packaged and delivered to customers.

- Continuous Improvement: They actively participate in continuous improvement initiatives aimed at enhancing test processes, increasing efficiency, and reducing costs. This involves staying updated on emerging technologies, adopting best practices, and implementing innovative solutions.

Expertise and Skills Required

To excel in the role of a Wafer Test and Sort Engineer, individuals must possess a diverse set of skills and expertise. Here are some key attributes required for success in this field:

- Technical Proficiency: A strong foundation in semiconductor physics, electrical engineering, and integrated circuit design is essential. Wafer Test and Sort Engineers must have a deep understanding of semiconductor manufacturing processes, test methodologies, and equipment.

- Programming and Automation Skills: Proficiency in programming languages such as Python, C, or Perl is highly beneficial for developing test programs and automating test processes. Knowledge of scripting languages and automation tools enables engineers to streamline testing operations and improve efficiency.

- Analytical Thinking: The ability to analyze complex data sets, identify patterns, and draw meaningful conclusions is critical for effective test data analysis and defect diagnosis. Wafer Test and Sort Engineers must possess strong analytical skills and attention to detail to ensure accurate and reliable testing results.

- Problem-Solving Abilities: Semiconductor manufacturing involves encountering various challenges and technical issues. Wafer Test and Sort Engineers must exhibit strong problem-solving abilities to address defects, optimize test processes, and improve overall yield and quality.

- Communication and Collaboration: Effective communication skills are essential for collaborating with cross-functional teams, including process engineers, design engineers, and manufacturing personnel. Wafer Test and Sort Engineers must be able to articulate technical concepts, share insights, and coordinate efforts to achieve common goals.

- Adaptability and Learning Agility: The semiconductor industry is dynamic and constantly evolving. Wafer Test and Sort Engineers must demonstrate adaptability and a willingness to learn new technologies, methodologies, and tools to stay ahead of industry trends and maintain competitiveness.

Significance in Semiconductor Manufacturing

The role of Wafer Test and Sort Engineers is indispensable in semiconductor manufacturing for several reasons:

- Quality Assurance: By conducting comprehensive testing and sorting of semiconductor wafers, these engineers ensure that only high-quality chips are delivered to customers. This contributes to the overall reliability and performance of electronic devices powered by semiconductor technology.

- Yield Enhancement: Wafer Test and Sort Engineers play a crucial role in optimizing manufacturing processes to improve yield and minimize defects. By identifying and addressing root causes of defects, they help enhance production efficiency and reduce waste, ultimately leading to cost savings for semiconductor companies.

- Time-to-Market Acceleration: Efficient testing and sorting processes facilitated by Wafer Test and Sort Engineers enable semiconductor companies to accelerate time-to-market for new products. By quickly identifying and resolving defects, they help expedite the transition from prototyping to mass production, allowing companies to capitalize on market opportunities more effectively.

- Customer Satisfaction: Ensuring the quality and reliability of semiconductor devices is essential for maintaining customer satisfaction and loyalty. Wafer Test and Sort Engineers play a vital role in meeting customer expectations by delivering high-performance chips that meet stringent quality standards.

Conclusion

In the intricate landscape of semiconductor manufacturing, Wafer Test and Sort Engineers serve as guardians of quality, reliability, and performance. Their expertise in developing test strategies, analyzing data, and optimizing processes is indispensable for ensuring the functionality and integrity of semiconductor devices. As technology continues to advance and demand for semiconductor products grows, the role of Wafer Test and Sort Engineers will remain paramount in driving innovation and excellence in this dynamic industry.